Reimagining Manufacturing with AI-Driven Precision

The Hidden Cost of Inefficiency

Even the most advanced manufacturing facilities face persistent operational challenges:

- Unplanned downtime that stops production lines without warning.

- Delayed responses due to disconnected data and legacy systems.

- Reactive maintenance cycles instead of proactive care.

- Inefficient inventory control leading to overstock or costly shortages.

- Limited visibility into performance metrics across plants or shifts.

These gaps don’t just impact operations, they erode margins, weaken competitiveness, and slow the pace of innovation.

When Small Inefficiencies Snowball

The manufacturing environment is unforgiving. A single weak link can ripple through the entire chain:

- Production delays cause missed delivery deadlines.

- Inaccurate forecasts result in overproduction or waste.

- Unplanned repairs drain budgets and disrupt schedules.

- Idle teams reduce workforce efficiency and morale.

- Customer dissatisfaction leads to repeat business loss.

AI That Works Where It Matters Most

Think AI delivers manufacturing intelligence that is both powerful and practical. Our tailored solutions target the most critical operational touchpoints:

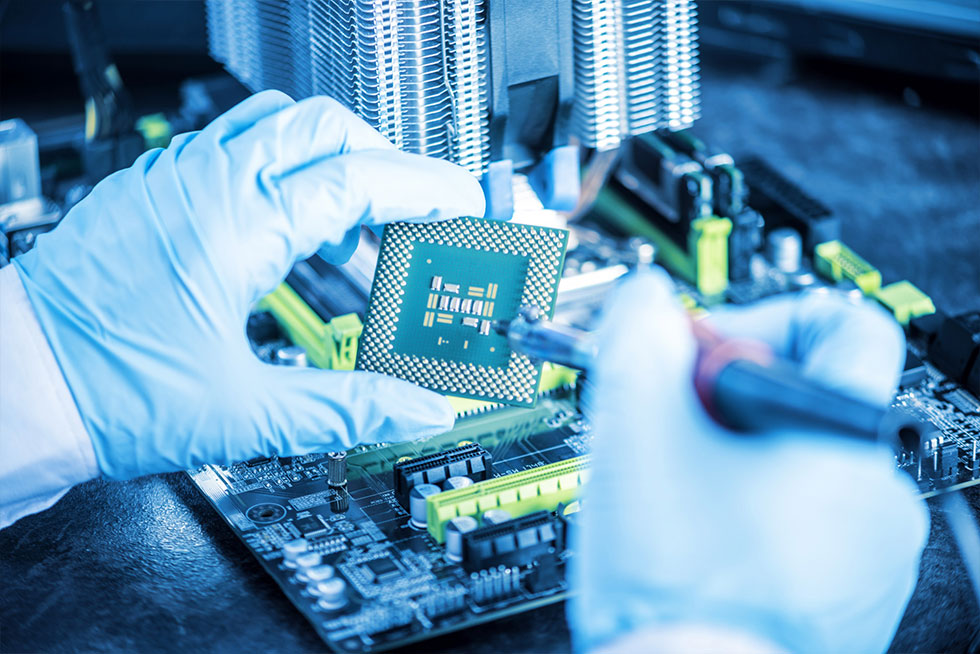

Predictive Maintenance

Anticipate equipment failure before it happens.

Real-Time Inventory & Supply Chain Analytics

Keep stock lean, accurate, and demand-aligned.

Demand Forecasting Models

Plan production with confidence and agility.

Production Performance Dashboards

Instant, visual, and actionable plant-wide insights.

AI Product Manual Assistants

Troubleshooting and operational guidance on demand.

All tools integrate seamlessly with your current systems, delivering immediate value without workflow disruption.

Measurable Gains, Market Advantage

Our manufacturing clients see a transformation not just in operations, but in business outcomes:

- Up to 30% reduction in unplanned downtime.

- 15–20% inventory optimization, freeing working capital.

- Faster decision cycles powered by live data.

- Improved delivery reliability building customer trust and loyalty.

- Increased plant efficiency without increasing headcount.

Proven Results. Real Business Impact.

Across industries, leaders with a progressive mindset partner with Think AI to transform how work gets done using Generative AI, Agentic AI, and advanced analytics. Whether it is about quick responses during emergencies or smarter sales predictions, our AI solutions yield results as per industry vertical. These outcomes are quick and measurable.

Manufacturing

60% reduction in unplanned downtime through AI-powered predictive maintenance.

Healthcare

AI-optimized discharge planning increased bed capacity by 20% without expanding infrastructure.

Public Sector (Transportation)

Agentic AI enabled real-time ferry rerouting, cutting emergency response time by 50%.

Retail & Professional Services

AI-driven sales forecasting improved prediction accuracy by 30%, helping teams plan smarter.

Utilities

AI-based pole inspections prevented two major fire incidents enhancing public safety and compliance.

Learn how we can help you with your manufacturing technology needs

AI Readiness Assessment & Strategy

AI Proof of Concept

(POC)

AI Automation &

Intelligent Agents

AI-Powered

Analytics

Copilot Studio / No-Code

AI Solutions

Our Case Studies

View some of our work and case studies for clients. We will work to deliver that strategy by building out your existing campaigns, or establishing accounts at new networks.

You have questions. We have answers.

Our tools are integration-first, they work alongside your current ERP, MES, and IoT systems. Our clients do not require us to make amendments in their infrastructure to see results.

Yes. By analyzing equipment data in real time, our predictive models are equipped to detect early warning signs of failure, allowing you to schedule maintenance proactively, often preventing breakdowns entirely.

Absolutely. Your data stays safe and confidential.

While every plant is different, clients typically see:

- Up to 30% less downtime

- 15–20% inventory optimization

- Faster decision-making with live operational data

- Improved customer delivery performance

We begin with a manufacturing intelligence assessment which is effective in mapping your current operations, identify quick-win opportunities, and recommend an AI adoption roadmap tailored to your business.